THE ULTIMATE GUIDE TO SUBLIMATION PRINTING IN THE SPORTS INDUSTRY

If you’re involved in the sports industry, particularly as part of a sports club or team, you’ve likely heard of sublimation printing.

But what exactly is sublimation printing, and how does it impact the world of sports apparel?

In this comprehensive guide, we’ll explore everything you need to know about sublimation printing and its role in revolutionizing the sports industry.

UNDERSTANDING SUBLIMATION PRINTING

What is Dye-Sublimation Printing?

Sublimation printing is a cutting-edge technique used to transfer dye onto fabrics, creating vibrant and long-lasting designs. Unlike traditional methods that apply ink on the surface, sublimation printing infuses the dye directly into the fabric fibers, resulting in superior color retention and durability.

This process involves printing the design onto special transfer paper and then using heat and pressure to sublimate the ink into a gas, which bonds with the fabric at a molecular level. The result is high-quality, fully customizable prints that are ideal for sports uniforms, activewear, and promotional merchandise.

How Does Dye-Sublimation Printing Work?

Sublimation printing operates by transforming solid ink into a gas without passing through a liquid phase. First, the desired design is printed onto specialized transfer paper using sublimation ink. Next, the paper is placed onto the fabric and subjected to heat and pressure using a heat press. Under the influence of heat, the ink sublimates, turning into a gas and permeating the fabric’s fibers.

Upon cooling, the ink solidifies, resulting in a vibrant, durable, and wash-resistant print directly infused into the fabric. This process ensures excellent color retention and sharp detail, making sublimation printing ideal for sports uniforms and promotional apparel.

Benefits of Sublimation Printing in the Sports Industry

Sublimation printing offers numerous benefits in the sports industry. It allows for vibrant, full-color designs with intricate details, ensuring eye-catching uniforms that stand out on the field or court. The process results in prints that are fade-resistant, durable, and capable of withstanding rigorous use and frequent washing.

Additionally, sublimation printing enables customization without additional costs, allowing teams like yours to incorporate logos, names, and numbers seamlessly. Its ability to print directly onto fabric ensures breathability, moisture-wicking properties, and a lightweight feel, enhancing comfort and performance for athletes. Nightfox specializes in providing high-quality custom jerseys utilizing sublimation printing technology.

Limitations of Sublimation Printing

While sublimation printing offers many advantages, it also has its limitations. One of the main drawbacks is that it can only be used on polyester or polyester-coated substrates, limiting the range of materials available for printing. Additionally, sublimation printing is not suitable for dark-colored fabrics, as the dyes are transparent and may not show up well on darker backgrounds.

Another limitation is that it requires specialized equipment and expertise, making it less accessible for smaller businesses or individuals without access to these resources. Despite these limitations, sublimation printing remains a popular choice for producing high-quality, custom-designed apparel in the sports industry.

Did you know that?

Sublimation printing was first invented by Samuel Simon in Manchester, England, in 1957. His pioneering work laid the foundation for the modern sublimation printing process used in various industries today.

DYE-SUBLIMATION PRINTING PROCESS

Preparing the Design

Preparing the design for sublimation printing involves several key steps. First, the design is created digitally using specialized software, ensuring precise placement of graphics, logos, and text. Once the design is finalized, it is printed onto transfer paper using sublimation inks. The printed transfer paper is then placed onto the fabric substrate and heat pressed at high temperatures.

During this process, the sublimation inks vaporize and penetrate the fabric fibers, resulting in vibrant, long-lasting prints. Careful attention to detail during the design and printing process ensures the best possible outcome for custom sublimated apparel, including Nightfox jerseys.

Transfer Process

In the transfer process of sublimation printing, heat and pressure are applied to the printed paper, causing the dye to sublimate and penetrate the fibers of the fabric. This results in vibrant, long-lasting colors that are embedded within the material, rather than sitting on the surface.

After the transfer, finishing touches such as cutting and sewing are done to create the final product, ensuring quality and precision in every detail.

SUBLIMATION VS. TRADITIONAL PRINTING METHODS

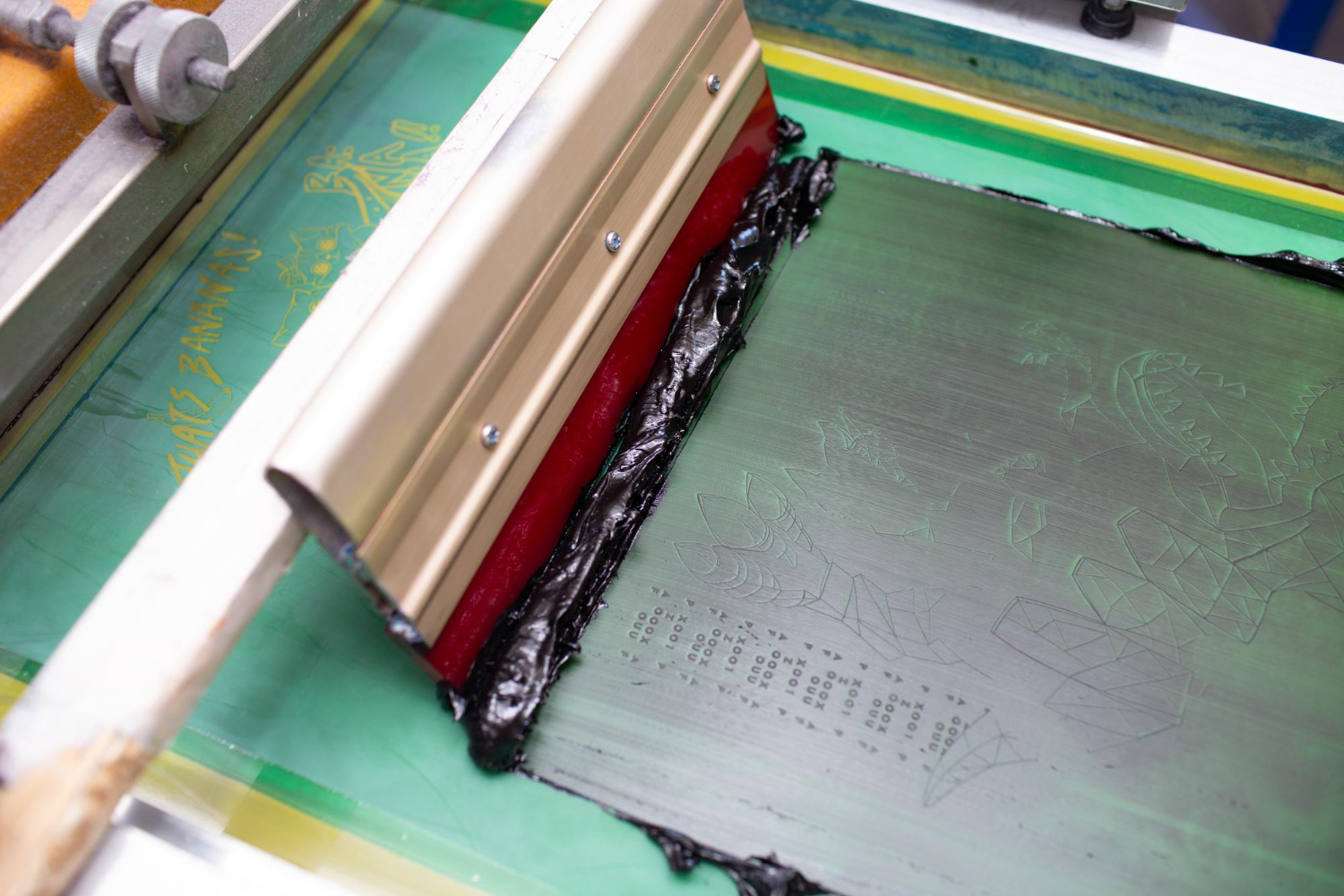

Comparison with Screen Printing

Compared to screen printing, sublimation printing offers several advantages in the sports industry. While screen printing involves applying layers of ink onto the surface of the fabric, sublimation printing infuses the dye directly into the fibers, resulting in vibrant, fade-resistant colors that won’t crack or peel over time.

Additionally, sublimation printing allows for intricate designs with unlimited colors and details, making it ideal for custom jerseys and uniforms.

Comparison with Heat Transfer Printing

Sublimation printing, compared to heat transfer printing, offers distinct advantages and disadvantages in the sports industry. While both methods involve transferring designs onto fabric, sublimation printing integrates the dye directly into the fibers, resulting in vibrant, long-lasting colors that won’t crack or fade.

However, sublimation printing requires polyester or polyester-coated substrates, limiting its application to certain materials. Heat transfer printing, on the other hand, can be applied to various fabric types but may result in less vibrant colors and a less durable finish.

The Versatility of Sublimation Printing

Sublimation printing is incredibly versatile, extending beyond jerseys and uniforms to various apparel items like T-shirts and activewear, as well as hoodies and jackets. It’s also ideal for producing accessories and merchandise such as caps, bags, and towels.

Beyond apparel, sublimation can be applied to create vibrant signage, banners, flags, and personalized gifts like mugs, phone cases, and mouse pads, offering endless possibilities for customization and branding.

Did you know that?

The total revenue worldwide in the sublimation business is estimated to be around $3 to $5 billion annually, reflecting the widespread adoption of this printing method across various industries, including sports, fashion, and advertising.

FACTORS TO CONSIDER WHEN CHOOSING SUBLIMATION PRINTING

Fabric Selection & Color Reproduction

Choosing the right fabric is crucial for optimal color reproduction in sublimation printing. Fabrics with a high polyester content yield the best results due to their ability to hold vibrant colors and intricate details.

The sublimation process ensures that colors are reproduced accurately and vividly, resulting in stunning, long-lasting prints that retain their vibrancy wash after wash. When paired with the right fabric, sublimation printing offers unmatched color reproduction and durability, making it a preferred choice for custom apparel and merchandise.

Durability & Cost Considerations

Durability and cost considerations are essential factors when choosing sublimation printing for custom apparel. Sublimation prints are highly durable, as the ink becomes part of the fabric, resulting in prints that resist fading, cracking, and peeling.

While the initial cost of sublimation printing may be higher compared to other printing methods, its long-term durability makes it a cost-effective option.

Additionally, sublimation printing allows for customization without additional costs, making it an economical choice for producing high-quality, long-lasting garments.

TIPS FOR DESIGNING SUBLIMATION PRINTS

Understanding Color Profiles

Understanding color profiles and choosing the right design software are crucial steps in the sublimation printing process. Color profiles ensure accurate color reproduction, consistency, and vibrancy in the final print. It’s essential to use design software that supports CMYK color mode and allows for precise color adjustments.

Adobe Photoshop and Illustrator are popular choices due to their robust features and compatibility with color management systems. By selecting the appropriate color profile and design software, designers can ensure optimal results and create stunning custom apparel with vivid, true-to-life colors.

Incorporating Branding Elements

Incorporating branding elements and maximizing design space are essential aspects of creating impactful sublimation prints. Brands can enhance their identity by integrating logos, slogans, and brand colors seamlessly into the design.

Maximizing design space involves strategic placement of elements to create a cohesive and visually appealing composition. By utilizing the entire surface area of the garment or product, designers can showcase branding elements effectively while maintaining balance and readability.

This approach allows brands to leave a lasting impression and communicate their message clearly through custom sublimation prints that stand out in the competitive market.

Did you know that?

The FESPA Global Print Expo is one of the best events to explore the latest advancements in sublimation printing technology. Held annually, it offers a comprehensive showcase of equipment, materials, and techniques for sublimation printing.

FINDING A RELIABLE SUBLIMATION PRINTING PARTNER

Researching Printing Companies

Finding a reliable sublimation printing partner is crucial for ensuring high-quality results and a smooth process. Look for a company with extensive experience in sublimation printing, a proven track record of delivering excellent products, and a reputation for reliability and customer service.

Additionally, consider factors such as production capacity, turnaround time, and flexibility in accommodating custom requests.

By teaming up with a reputable sublimation printing provider such as Nightfox, you gain access to comprehensive services encompassing design, printing, and production, all conveniently located in our European factories. While Nightfox stands out for its quality and reliability, there are also other reputable factories across Europe that excel in sublimation printing.

COMMON QUESTIONS

Can you do sublimation on Dri Fit shirts?

Yes, absolutely! At Nightfox, our Tech T-shirts are fully customizable and printable using sublimation, perfect for Dri Fit shirts. You can design and order even a single shirt with an all-over print, without any minimum order requirement. Additionally, our shirts feature a raglan cut and a fabric texture that allows unrestricted movement, particularly around the shoulder and torso areas. This makes them ideal for active and dynamic use.

For sublimation printing on Dri Fit or similar polyester fabrics, the typical temperature required is around 385-400°F (196-204°C). The process usually involves pressing the fabric under this temperature for about 30-45 seconds. It’s essential to ensure that the Dri Fit material is made predominantly of polyester because sublimation ink only binds permanently with polyester fibers. Materials with lower percentages of polyester might not produce as vivid or durable results.

Can I sublimate on 50 cotton / 50 polyester?

Yes, you can sublimate on a fabric blend that is 50% cotton and 50% polyester, but there are some important considerations to keep in mind:

Color Vibrancy: Sublimation ink binds best with polyester fibers. Therefore, the color vibrancy and brightness on a 50/50 blend will be less intense compared to a 100% polyester fabric. The colors may appear more muted because only the polyester fibers will absorb the dye, leaving the cotton fibers largely uncolored.

Wash Fastness: The durability of the print on a 50/50 blend may not be as robust as on 100% polyester. The ink might fade more quickly over time, especially after multiple washes, since the dye does not bind as effectively to cotton.

Pre-Treatment: For better results, it’s recommended to use a polyester spray pretreatment on the cotton-polyester blend fabric. This treatment can help the sublimation ink to better adhere to the fabric and enhance the vibrancy of the colors.

Heat Press Settings: Use the typical sublimation settings (around 385-400°F for about 30-45 seconds). However, always consider doing a test print first to ensure that the fabric can handle the heat without scorching and that the colors transfer effectively.

Expectations: Set realistic expectations about the outcome of sublimation on a 50/50 blend. The results will differ from those on 100% polyester, so it’s important to communicate this to customers or anyone else involved in the project to avoid any disappointment.

Conclusion

In conclusion, this guide serves as a comprehensive resource for understanding the intricacies of sublimation printing in the sports industry. From its origins and technical processes to its applications and considerations, we’ve explored the various facets of this versatile printing method.

With its ability to produce vibrant, durable, and customized designs, sublimation printing continues to revolutionize the world of sports apparel and merchandise. Whether you’re a sports team, apparel manufacturer, or enthusiast, harnessing the power of sublimation printing can elevate your brand and enhance your product offerings.

Get Social